Mine Safety: Seven Ways to Make Mines Safer and More Efficient

By Latam Mining

September 15, 2020 - In the early part of the 20th century the mining industry in the USA would typically suffer more than 1,000 fatalities a year.

In the 1990s that figure reduced to less than 100 deaths per year and in recent years the annual total has fallen further.

Technology and increased regulation have led to improvements in mine safety and helped make mining a less dangerous profession.

In 2017 according to the US Department of Labor there were 15 fatalities in coal mines and 13 in metal/non-metal operations.

This year Mining Technology has been trying to help play a part in reducing this number yet further by launching a dedicated Mining Safety section on the site sponsored by Carroll Technologies Group (a supplier of mining safety equipment and solutions to mines in north America).

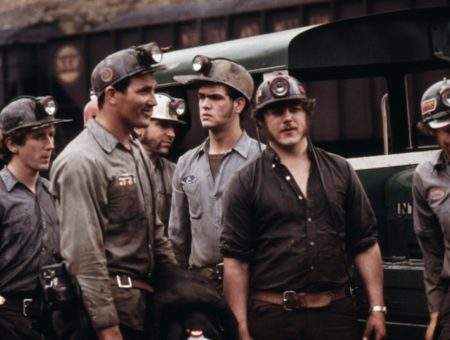

A group of Virginia coal miners awaiting a shift in 1974

Here are seven ways mine operators can make their facilities safer (and more efficient).

1) Invest in wireless underground communications

Swap your hard-wired pagers for a mobile leaky-feeder communications system. This is a handheld radio which every worker who has one to communicate with colleagues underground and also allows miners (and equipment) to be quickly located. Effective communications and tracking technology is essential in case of an accident underground.

2) Automation can improve safety underground

Carroll Technologies Group CEO Tom Bannister said: “If you take human error out of it you can have a lot safer working environment, in most cases. I do [see automation becoming more prominent] and there are a lot of devices in mining that are that way. We’re doing a lot of things with remote, wireless remote controls now, so the individual doesn’t have to be on that piece of machinery to run it – he stays out of harm’s way and doesn’t have to get under unsupported top, or stay out of hazardous areas and check equipment remotely.”

3) Using data to improve mine safety

Atmospheric monitoring information collected through leaky-feeder devices can be used to provide mine managers with vital safety data.

Carroll Engineering president Allen Haywood said: “One of the things they use that data for, that they want to look at and serve operations, is air flow.

“It’s critical for these operations to have proper ventilation to keep air flowing throughout the mines underground, and they can measure, on this system, the amount of air flow in particular areas.

“And that’s recorded, in case they want to go back and look and see what that air flow is, they can go back and look at the history of that.”

4) How drones can improve mine safety

Joe Carr, of Inmarsat, told Mining Technology: “ Freeport-McMoRan is already using drones to create steeper pit slope angles in its mines, reducing the stripping ratio and amount of waste rock hauled before ore can be extracted. These drones not only scan the mines from perspectives that are dangerous and near-inaccessible to humans, they also instantaneously communicate any information they pick up. This makes for a more rapid and detailed analysis of the mine slopes without having to deploy highly skilled geologists or geotechnical engineers into an inherently hazardous environment or affecting production by closing haul roads.

“With machines becoming progressively more capable of acting with little manual intervention, a future where adaptable and autonomous machines carry out the on-site, operational tasks of mining while human employees monitor them remotely looks probable and highly profitable.”

5) Kit miners out with self-contained rescuers

Self-contained rescuers are a portable device which provides a supply of breathable oxygen to miners should they become trapped underground, or should poisonous gases leak into mineshafts.

The standard SCSR features an oxygen scrubber, which can chemically remove impurities from the atmosphere to provide a miner with breathable oxygen.

Suppliers like Carroll Technologies can also provide an oxygen-producing unit for more specialised operations. This device is rarer in metal/non-metal mines, but is becoming increasingly widespread. It consists of a small tank filled with oxygen to which a miner has immediate access.

Many of the most significant mining accidents occur due to a lack of oxygen or the presence of poisonous gases.

6) Consider switching from wire to synthetic rope

According to Donna Poll of Samson rope: “When wire rope breaks there’s a danger of damaging the surrounding area and people. Synthetic rope has much more predictable recoil properties.”

She said that because synthetic rope is much lighter than wire there is also less likelihood of strain and sprain injuries when handling it.

7) Put systems in place to avoid collisions underground

Collisions involving heavy vehicles are one of the major causes of injuries underground.

One way to reduce the risks is to install proximity detection devices which sound an alarm when a large piece of equipment is getting close to another one.

Carroll Engineering president Allen Heywood explained: “As an example, the driver of a large rock truck would actually have a screen – what they call a hardened, rugged screen – and tags would be installed on personnel or smaller pieces of equipment if they just want the monitor to see where those are. They don’t necessarily need to see the large piece of equipment; the one that has trouble seeing and identifying has the screen in his vehicle, and they can put one of these tags on anything.”

Satellite tracking technology can be used to avoid collisions between vehicles and equipment on the surface of mines.

Mining Technology’s Mining Safety content is supported by USA mining safety specialists Carroll Technologies Group.