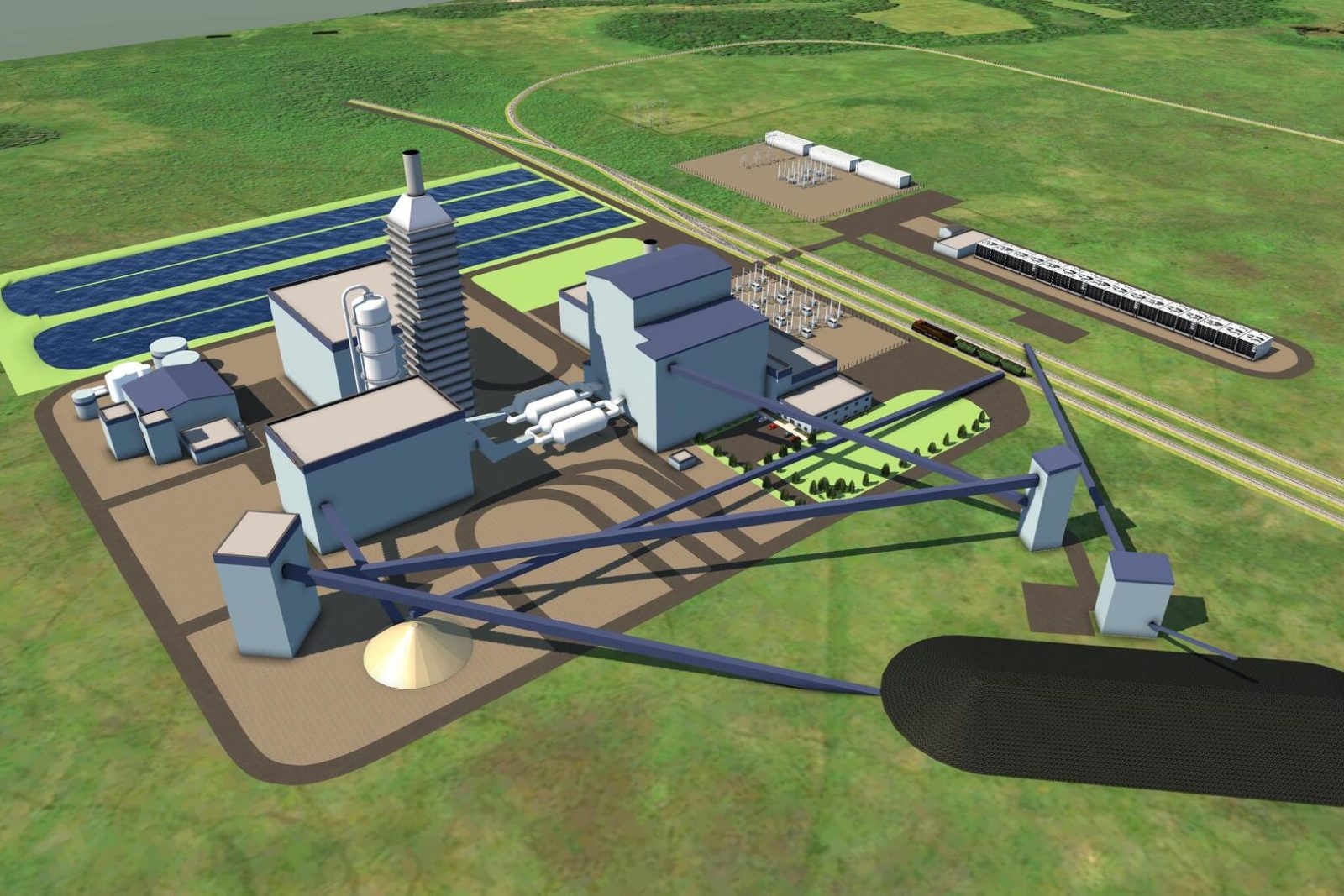

DOE Awards $25 Million for Next-Gen Coal-Fired and CCUS Project in Illinois

By Prairie Research Institute

November 12, 2020 - A three-year Illinois project to design a next-gen coal-powered generation plant has received $25 million in federal funding.

The U.S. Department of Energy awarded the funding to the Prairie Research Institute, which is leading the effort. The plant design would include multiple techniques for reducing emissions, capturing and re-using carbon dioxide.

“With this project, we’re bringing together different pieces of the sustainable energy puzzle,” said Kevin O’Brien, who is principal investigator of this project and leads the Illinois Sustainable Technology Center (ISTC) and Illinois State Water Survey (ISWS). “PRI’s scientists have been advancing emissions reduction, carbon capture, and carbon utilization, and this gives us an opportunity to combine all of our expertise and experience in these areas to deliver greater impact.”

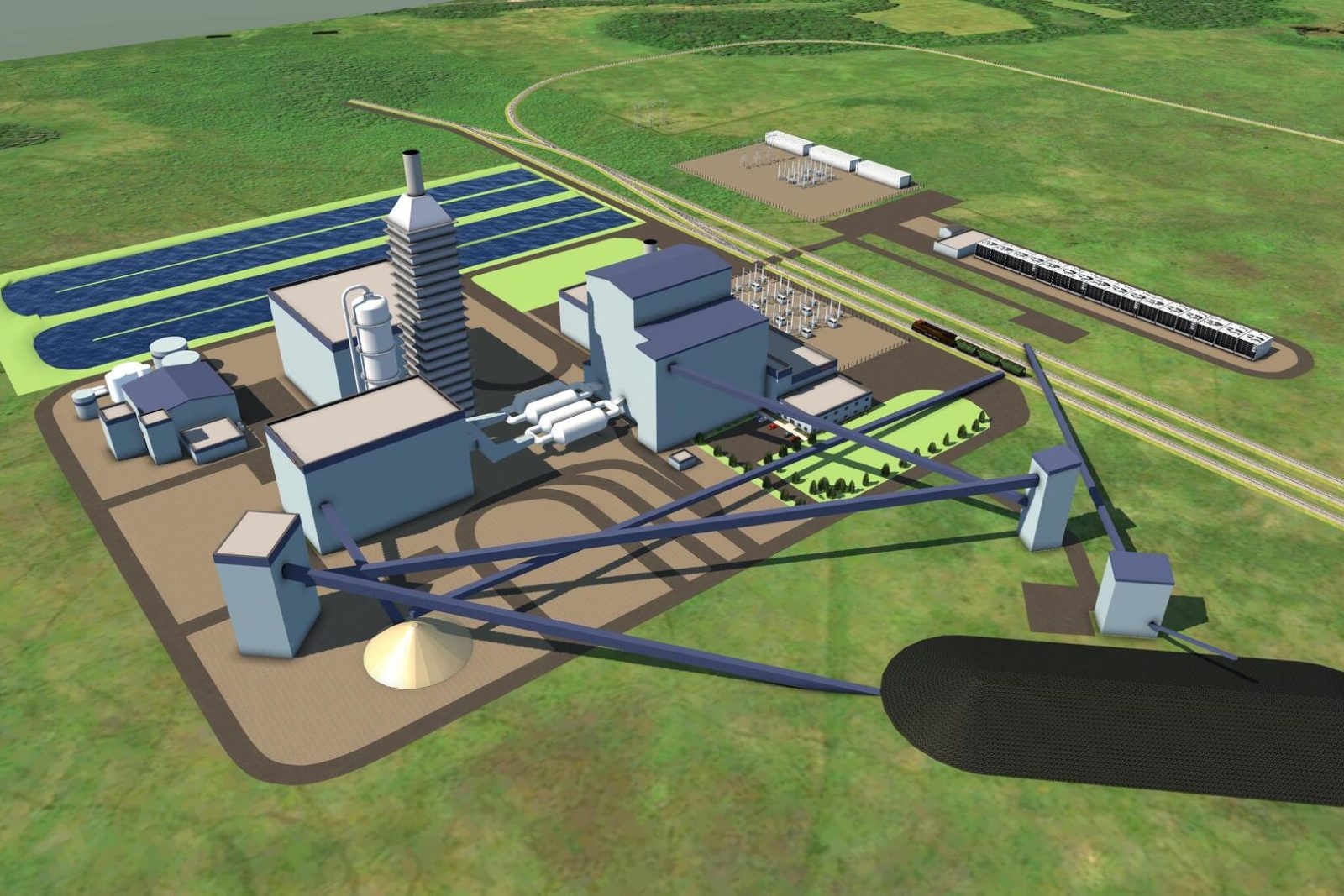

The project is called Front-End Engineering Design Study for Hybrid Gas Turbine and USC Coal Boiler (HGCC) Concept Plant with Post-Combustion Carbon Capture and Energy Storage System at City, Water, Light and Power Plant.

It is part of the DOE’s Coal FIRST Initiative trying to spur innovation in coal-fired generation.

Several subawardees will be focus on specific aspects of the project. Doosan Heavy Industries is developer of the HGCC technology, while Kiewit and Global Algae Solutions also will participate.

Other companies involved include Barr Engineering, working on firing systems; Microbeam (fuel treatment), Envergex (control systems) and the University of South Dakota (additional coal sources).

Components of the design proposed by the Prairie Research Institute and collaborators include a 270-MW ultra-supercritical coal boiler subsystem, an 87-MW gas-fired combustion turbine generator subsystem, 50-MW energy storage, post-combustion CO2 capture and algae-based CO2 utilization subsystems.

“While these individual components have been used before, they’ve never been combined in this way,” O’Brien said. “Part of our aim with this project is to standardize and modularize these components, so this design can be replicated and more easily maintained. We hope this could become the global standard for innovative, low-emission coal-fired power.”

An ultra-supercritical system operates at intense pressure, which means steam is more efficiently converted to the mechanical energy that drives the turbines to produce electricity. Increased efficiency means less coal is needed for each megawatt of power produced, reducing emissions.

Including both natural gas combustion and energy storage will provide greater flexibility and resiliency. Varying demand is tough on coal-fired boilers, because frequent shut-downs and start-ups cause huge swings in temperature and pressure that cause stress on their components.

Natural gas systems don’t suffer the same stresses; they can ramp up quickly to meet surging demand and can be shut down when demand drops. Likewise, the energy storage subsystem will enable the plant to store energy to meet fluctuating consumer needs for power.

An additional benefit is that the exhaust from the natural gas system can be used to pre-heat the coal system, reducing how much coal needs to be used.

The proposed design also includes technology, developed by Linde PLC BASF, to capture carbon emissions before they reach the environment. ISTC is overseeing a large pilot test of the performance, safety, and environmental compliance of this technology at Springfield’s City Water, Light, and Power (CWLP) plant.

Finally, the captured CO2 will be used to help grow algae that can be converted into biofuel, animal feed, or biochar soil supplement.

The Future of Coal-Fired Generation is a key topic both in the virtual POWERGEN+ series and the eventually live POWERGEN International.

.gif)