September 15, 2022 - Business is booming for companies associated with the coal mining industry, with no end in sight.

That is the message from exhibitors at the 2022 Bluefield Coal & Mining Show, which started Wednesday and runs through Friday afternoon at the Brushfork Armory.

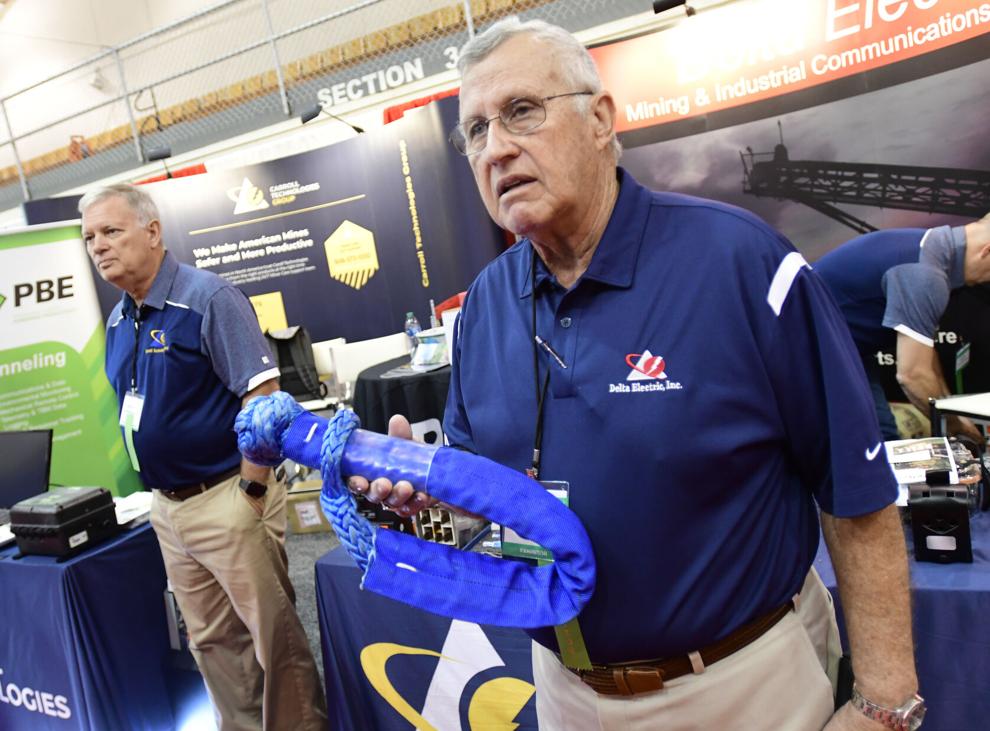

Mike Hastings, chairman of the board for Delta Electric, said his company and Carroll Technologies were at the coal show together this year since they routinely do business together.

Mike Hastings of Delta Electric Inc., shows synthetic rope that is strong enough to take the place of steel cable at the Bluefield Coal and Mining show.

Staff photo by Jessica Nuzzo

“We do mining distribution and safety products … and electrical products,” Hastings said, with one company in Harlan, Ken. and the other in Logan, adding that he is at the coal show every year.

“We have always participated,” he said, adding that business this year is booming.

Both businesses have been “fantastic,” Hastings said. “We’ve got people screaming for stuff now. The supply chain is backed up. We purchase way ahead, but still have a hard time getting it (products).”

That even includes traditional products like hand-held radios, which every coal miner has.

Hastings said business has increased about 500 percent from the recent downturn.

He said the companies are separate entities but work together distributing different products, which include fiber-based ropes that are stronger and safer to use than the traditional steel cables and proximity alert detectors on machinery that prevent accidents, among many other products.

Alan Haywood, president of Carroll Technologies, said the rope, manufactured by Samson, is synthetic, but a rope the same diameter of a steel cable is stronger and safer with no dangerous shrapnel if it breaks.

“It is really truly amazing,” he said, and can be used in about any application a cable can be used.

The collision avoidance electronics is on equipment, like dozers, and automatically slows them down, much like it does in automobiles.

“We can put it on any type of equipment,” said.

Hastings said business is so good that it is almost “scary.”

Conn-Weld Industries is a Princeton-based company that manufactures custom-designed screening and separation equipment for mining/aggregate and other industries.

Marvin Woodie, a mechanical engineer and company president, said the business started in 1975 with manufacturing screen media used for washing and processing coal, but the company started fabricating more equipment related to various screening in the 1980s and went global in the 1990s.

“A lot of things have to be screened,” he said, including food. “We make the entire equipment (for the screening process of products).”

Woodie said the facility in Princeton has 400,000 square feet of production space, but that is not enough.

“We are getting ready to add 100,00 square feet of production space,” he said, bringing the total to 500,000 square feet. “Business has been good.”

Woodie said the company has diversified into aggregates and other areas, and the extra work has required the company to expand its workforce, from 162 employees in 2020 to more than 250 now, plus adding needed equipment.

This is Conn-Weld’s first year participating in the coal show and he said he was invited to the show by Peters Equipment and Ramsey Industrials because the companies work together.

“It will be a good experience for us,” he said. “We already know a lot of people in the coal mining industry all over the world.”

Jeff Grose, sales executive with Peters Equipment in Bluefield, Va., also said business is booming.

“We are doing very well,” he said of he current state of business. “The mining industry is doing well across the board.”

Peters Equipment designs and manufactures mining equipment and machinery and is a global company.

Grose said the company can build structures from the ground up for a variety of industries, like aggregates.

“Business right now is doing so much better,” he said. “It is amazing. I think everyone is doing well.”

Grose said it is so busy the company has had to pass up some work.

“We don’t have to do just any job,” he said, unlike in the past when choices were slimmer. “We’ve got so much to do we can pick and choose”

Josh Burns, senior sales engineer with Komatsu Mining’s Bluefield, Va. facility, said the company struggles to keep up with the demand.

“The supply chain is a big time struggle right now trying to meet the demands of the customers we have,” he said, “but I think we are doing a great job.”

Komatsu builds equipment for mining and various industries and purchased Joy Global in 2017.

Burns said things have changed a lot since the 1019 coal show.

“Business has definitely shifted,” he said. “We are trying to keep up with the orders. Obviously, each order has its own nuances as far as what we need to meet and deliver. But we are working with our vendors to see what we can get and we will get the machines and get them out to our customers.”

Burns said the equipment is about the same as it was three years ago but the company is working on some new advancements in the mining industry as far as automation.

“The battery hauler, with the lithium battery, we are trying to get it approved so we can actually use it in the coal mining industry,” he said of another advancement. “We are using it in industrial minerals right now.”

Burns said if more products were available now (not impeded by supply chain issues) the company would need to expand its workforce.

“But we are pretty stationary on that right now,” he said.

The businesses reflect the upbeat atmosphere at the coal show, which is featuring 165 exhibitors with thousands of industry representatives expected to attend the event and see the latest in industry products.